Premier Aluminum Llc for Dummies

Table of ContentsSome Known Facts About Premier Aluminum Llc.The smart Trick of Premier Aluminum Llc That Nobody is Talking AboutRumored Buzz on Premier Aluminum LlcIndicators on Premier Aluminum Llc You Should KnowThe 10-Minute Rule for Premier Aluminum Llc

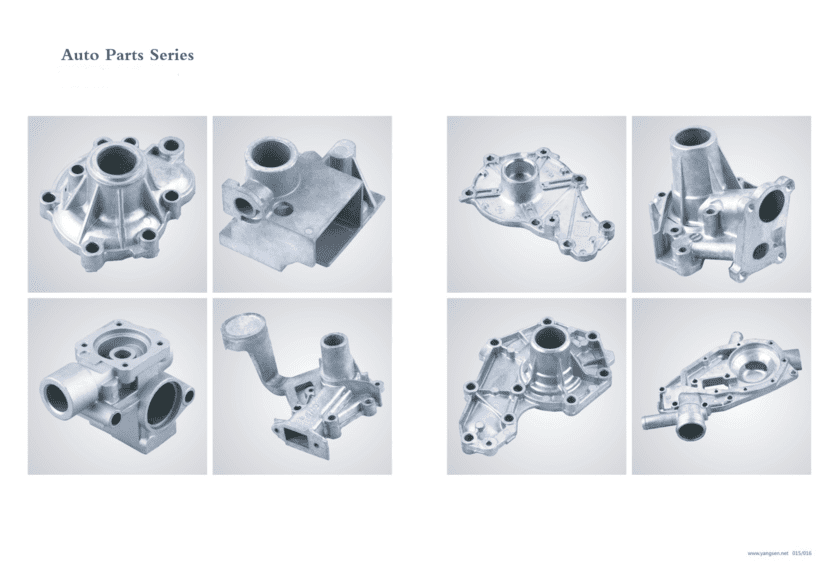

When picking a light weight aluminum shop for your production needs, it's crucial to study several aspects. Among the most essential elements to take into consideration is the experience and competence of the factory. Selecting a shop that has the right knowledge of the light weight aluminum spreading process, and the portfolio to show for it, aids to have a successful outcome for your project.Having the experience and sector expertise to engineer your spreadings for ideal production and high quality outcomes will certainly streamline the task. Producing light weight aluminum castings calls for a facility set of processes to accomplish the best outcomes. When selecting a new light weight aluminum foundry to partner with, guarantee they have extensive industry experience and are educated about all elements of the aluminum casting procedure: design, production, product evaluation, and product screening.

The factory must also have a tried and tested track record of delivering outstanding products that fulfill or exceed customer assumptions. Quality control ought to additionally go to the top of your checklist when selecting an aluminum shop. By dealing with a certified factory that adheres to the standards for quality assurance, you can secure the honesty of your product and ensure it fulfills your specifications.

Little Known Questions About Premier Aluminum Llc.

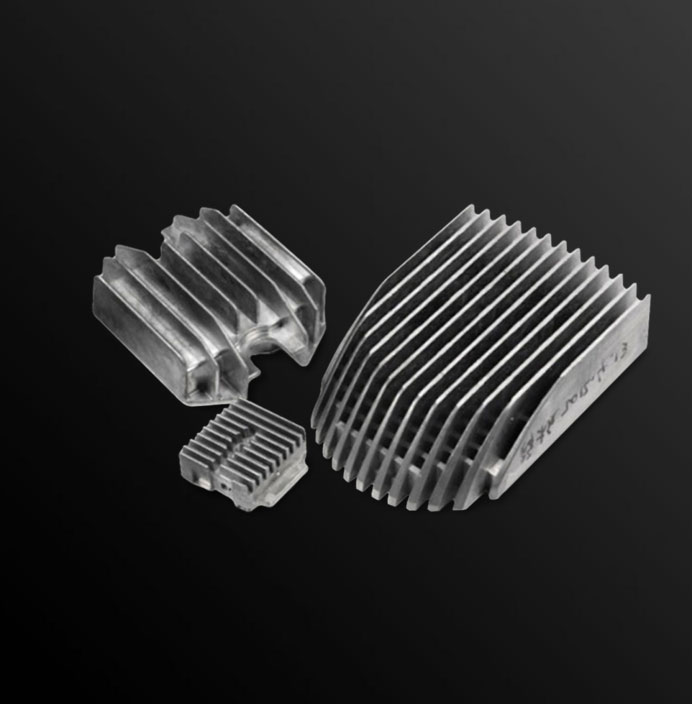

This specific process can be automated and duplicated. Different parts that extremely complicated forms can be produced using this process. Big quantities of parts can be created in simply a short period of time. Before you begin looking for a dependable light weight aluminum die wheel, there are some vital things that you need to do initially.

You have to ask on your own what kind of aluminum die castings you call for. After determining what you require, you need to specify the specs of the light weight aluminum die spreadings you need. Figure out the weight, thickness, size, and other specs of the light weight aluminum die-cast you call for. It would certainly additionally be a lot better if you could attract and show all the measurements of the light weight aluminum die-cast.

Do you understand just how much cash you have to invest in the items? In order to do this, the finest thing to do is to determine just how lots of aluminum diecasts you call for. After having this information, you can start looking into aluminum die-casting manufacturers. You can do this by merely typing the key words" Aluminum Your Domain Name die casting manufacturers" on the Google internet search engine.

Several of the concerns you need to ask on your own are whether they have actually experienced and trained drivers, for how long their company has functioned, or if they have some accomplishments. You can often get the solution to these inquiries from the producer's site. You can look into other internet sites or outside resources to confirm if the details offered on the supplier's web site is genuine.

The Definitive Guide for Premier Aluminum Llc

One more thing you have to consider is the maker's ability to create aluminum die-casting items. To put it simply, the quantity of items the supplier can create at a provided time. A few of the crucial questions you require to ask yourself are whether the maker can create a higher volume or can the maker satisfy your demands.

(https://soundcloud.com/premieraluminum11)Suppose your firm requires 10,000 pieces of particular machine parts from the manufacturer within one month? You bought this amount; nonetheless, the maker can just produce 5000 pieces of these maker components within one month (Foundries in Wisconsin). As an outcome, you won't have the ability to get the amount that you order on time

Indicators on Premier Aluminum Llc You Need To Know

Hence, it is very important that you need to ask if the producer is carrying out an in-house tooling process. Additionally, you have to ask the supplier how much the cost of in-house tooling is. The internal tooling procedure, which permits you to create unique styles and shapes can be an added price.

This facet straight correlates with the maker's manufacturing ability. You need to search for a supplier that can make sure quicker distribution of products. However, this ought to be carried out in such a way that high-quality standards are maintained. This can ensure that you can get your products promptly, and you can prevent missing out on those beneficial service chances.

This means that there are numerous choices that you can pick from. That is why it is considerably suggested that you ought to select a supplier that can create different kinds of light weight aluminum die-cast items.

Premier Aluminum Llc Things To Know Before You Buy

Usually, these light weight aluminum die-casting products will need some designs, machining, or finishing touches. Having this in mind, you need to look for a producer that can perform a variety of additional ending up works when pass away casting is done. Some instances of finishing operations include Chromating, CNC Machining, Sandblasting, Powder finish, Anodized, E-coating, Wet painting, Plating, and several even more.

Die spreading is just one of the most cost-efficient, precise, and protean production procedures worldwide minute. The process involves fitting molten significance, under stress, right into a relevant die (planet), and formerly strengthened it can be expelled and ended up (if essential) in a variety of ways. The passes away are [...].